In today’s fast-paced manufacturing and packaging industries, efficiency and sustainability go hand in hand. Companies are constantly searching for ways to streamline operations, cut costs, and reduce waste without compromising product quality. In the middle of these technological advancements, the automatic side sealing machine stands out as one of the most innovative solutions for modern packaging processes. Designed for precision, speed, and minimal material usage, this machine plays a crucial role in optimizing workflow while supporting eco-friendly production goals.

Understanding How the Machine Works

The Basics of Side Sealing Technology

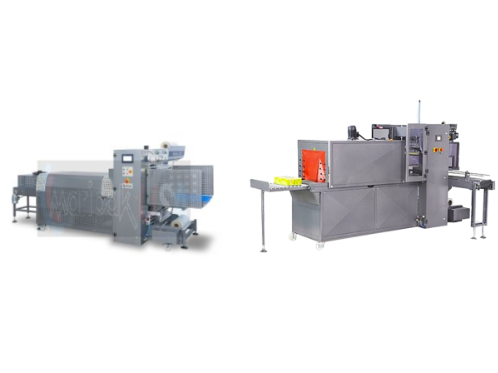

An automatic side sealing machine is designed to continuously wrap and seal products with shrink film. Unlike manual or semi-automatic sealers, these machines automatically detect, wrap, and seal each product as it moves along the conveyor system. Using sensors and advanced automation, they ensure consistent sealing accuracy and material usage.

This process typically involves feeding shrink film around a product, sealing one side while cutting off excess material. The sealed product is then sent to a heat tunnel, where the film shrinks tightly around it, resulting in a secure, professional finish.

Continuous Sealing for Maximum Output

One of the standout features of this equipment is its ability to perform continuous side sealing. This means that the machine can handle large production volumes without interruption. The continuous operation not only enhances speed but also ensures that every inch of film is efficiently used. With minimal start-and-stop action, companies can save time and reduce film waste significantly.

How It Reduces Material Waste

Precision Cutting and Sealing

A key benefit of an automatic side sealing machine is its precision. Manual packaging often leads to inconsistent cuts and unnecessary film usage. Automated systems, however, are engineered to measure and seal exactly according to the product’s dimensions. This precise measurement minimizes excess film usage and eliminates the need for additional trimming or adjustments after sealing.

Optimized Film Utilization

The machine’s advanced control systems calculate the ideal film length for each product, ensuring uniform wrapping and reduced film overlap. By minimizing the amount of film required per package, manufacturers can significantly lower overall material consumption. This results in cost savings and a more sustainable operation.

Reduced Human Error

Human involvement in packaging can lead to inconsistencies that waste both time and materials. The automation built into modern sealing machines virtually eliminates these errors. Sensors automatically detect product placement and alignment, ensuring each item is sealed correctly without the need for manual intervention.

Enhancing Sustainability in Packaging

Supporting Eco-Friendly Operations

As industries face increasing environmental regulations and consumer expectations, adopting sustainable practices has become a priority. Automated systems help companies move closer to these goals. By reducing waste, optimizing film usage, and lowering energy consumption, these machines support green manufacturing initiatives and contribute to a smaller carbon footprint.

Compatibility with Recyclable Materials

Many models are designed to work efficiently with recyclable shrink films, including biodegradable options. This versatility allows companies to switch to eco-friendly films without compromising packaging quality or performance. As a result, manufacturers can meet sustainability targets while maintaining production efficiency.

Increased Efficiency and Cost Savings

Streamlined Production

Automation allows companies to meet high production demands without increasing labor costs. With minimal manual handling, productivity increases while operational expenses decrease. This efficiency translates into quicker turnaround times and consistent product presentation.

Maintenance and Longevity

The durability of an automatic side sealing machine ensures long-term reliability. Built with high-grade materials and advanced engineering, these machines require minimal maintenance, reducing downtime and repair costs. Their ability to perform consistently under continuous operation adds value over time.

The Role of Automation in Modern Manufacturing

Consistency in Quality

Every package produced through automated sealing follows the same standards. This consistency not only enhances brand reputation but also minimizes product returns due to packaging errors. In industries where presentation and protection are critical, such as food, pharmaceuticals, and consumer goods, automation delivers unmatched reliability.

Integration with Other Equipment

These machines can easily be integrated with other automated packaging systems such as conveyors, labeling machines, or case packers. This seamless connectivity ensures a continuous and efficient production line that maximizes throughput while minimizing waste.

Applications Across Industries

E-commerce and Retail Packaging

In e-commerce and retail, presentation and protection are key. Automated side sealers ensure that products are neatly wrapped, tamper-proof, and ready for shipping. They also support fast-paced packaging lines where speed and precision are crucial.

Food and Beverage Industry

For food packaging, hygiene and product safety are top priorities. Automated systems ensure minimal human contact and secure sealing, preserving freshness and quality while maintaining compliance with industry regulations.

Industrial and Manufacturing Sectors

Manufacturers benefit from these systems’ ability to package bulky or irregularly shaped products without material wastage. From printed materials to electronics, the versatility of automatic sealers makes them ideal for diverse production needs.

Conclusion

The evolution of automated packaging technology has transformed how businesses approach production efficiency and sustainability. Machines that combine precision, speed, and eco-friendly operation offer tangible advantages in cost savings and waste reduction. For manufacturers seeking to achieve higher productivity and environmental responsibility, integrating advanced systems like the polyolefin shrink machine provides the perfect complement to an automated sealing setup, ensuring efficient, sustainable, and high-quality packaging for every product.